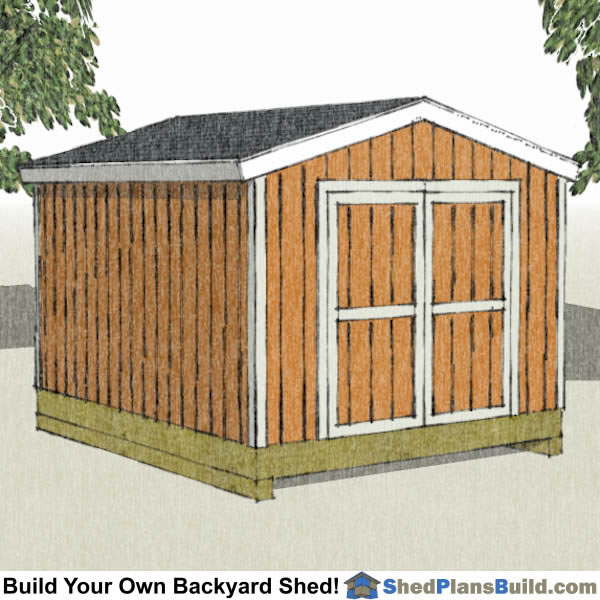

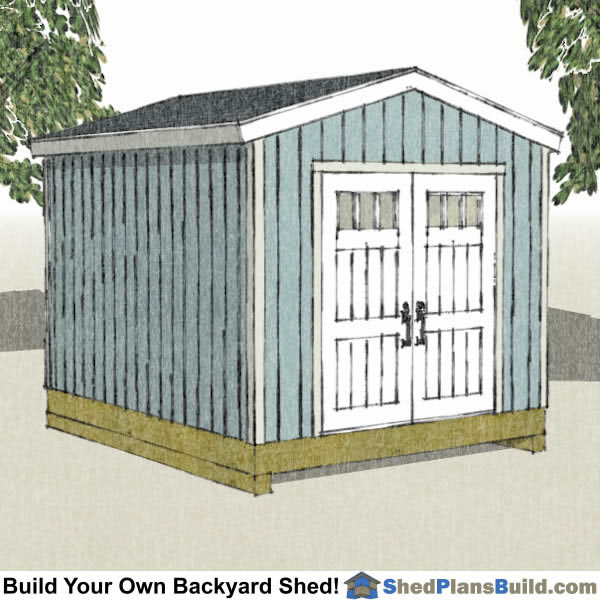

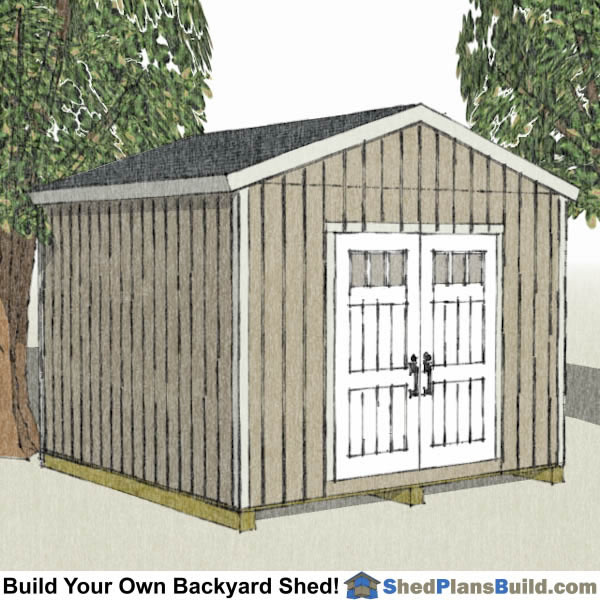

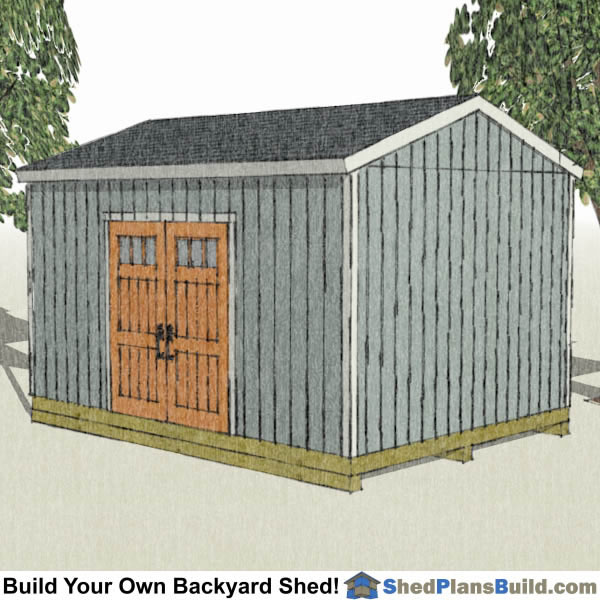

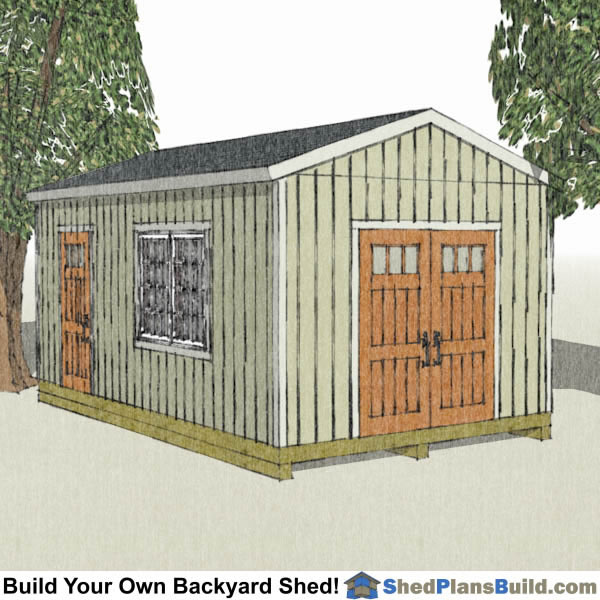

Backyard Shed Plans

Understanding Backyard Sheds

Like most storage sheds our Backyard Shed Plans are designed to be built anywhere you want. We use the term "backyard shed" to represent some simple design elements used to create a line of storage sheds that are simple to build and keep the costs down lower than comparative sheds of the same size. Costs are reduced by using a simple roof line. Design elements such as a lower slope roof with very little overhang makes them easier to frame and cost less to build because there is less lumber used without overhangs and less roofing used.

Wall Heights Explained:

7'-7" or 8'-1" Shed Wall Heights: The Tall Backyard Shed designs have a taller wall that allows the use of a factory built door or a home built door. The header is attached directly to the top plates and there is just enough room below it to install a factory built door. The use of of 7'-7" wall heights helps reduce construction costs because the 7'-7" wall height allows the siding to cover from the top plates to below the joint at the bottom of the walls to the floor framing. This eliminates the need to install blocking behind the horizontal siding joints on the walls because the joints will be over the top plate boards. If your walls are framed to 8'-1" tall you will have a horizontal siding joint that needs blocking behind it between every wall stud.

Our plans are drawn with a wall height of 7'-7" but you can also use 92 5/8" pre-cut studs to make the walls 8'-1" like a home is framed.

6'-6" Wall Heights: Backyard shed designs without the "Tall" designation are designed to have a home built door with the door header attached directly to the top plates and the wall heights at 6'-7". This is our lowest cost to build economy shed plans. The 6'-7" wall height Backyard Sheds only have the option for a shorter wall and they will not accomodate a factory built door. Our home built door for the shorter shed is 5'-10 1/2" tall.

Short Sheds: Our line of short sheds are designed to be "short". This means that they are below 6' or 8' tall. Some areas do not allow sheds taller than 6' in backyards and some do not allow 8' tall. The 8' version of our "short" sheds uses our 5'-10 1/2" tall shed door and the 6' "short" sheds use a door that is about 4' tall. Check with each respective plan to see what door is used.

Roof Styles Of Backyard Sheds

Gable Roof Sheds: Our economy backyard shed plans are designed using a gable roof. The gable design gives the classic backyard shed look with two sloping roof sides and a ridge down the middle. They use a 4 in 12 roof pitch unless they are in the "Short Shed" style.

Lean To Sheds: The lean to shed style has a single slope roof with a single ridge and one sloping roof plane. The lean to design works well up against another structure and keeps the water or snow running away from the adjacent structure. Some of the smaller short designs we use a lean to shed roof. You can find more lean to sheds in our Lean To Shed section.

Both the gable roof backyard sheds and lean to sheds have minimal roof overhangs to reduce construction labor and costs.

They are all designed to use asphalt shingles but the short sheds usually need a low slope asphalt shingle installation. This is typically just a layer of asphalt roll roofing under the shingles to keep the roof from leaking. Check with the roofing manufacturer to see what they recommend.

Foundation Plans For Backyard Sheds

We have several foundation options for your shed build, these include wood framed floor on pressure treated wood rails, pressure treated or steel floor framing on gravel bed, concrete slab, poured pier and concrete block pier. This is an explation of each of the shed foundation options for your storage shed.

Pressure Treated Wood Rails: This is one of the best ways to build an economical shed foundation. It consists of the treated wood rails being set directly on a bed of gravel

Treated or Steel Floor Framing: This is the most economical way to build your shed floor and foundation. It is built by setting the floor framing directly on a 4 inch thick layer of gravel. The floor framing must be pressure treated lumber or steel joists for the floor joists. The floor decking must also be pressure treated. The treated lumber costs a bit more but it offsets the cost of the eliminated rails used in the rail foundation design. One of the best reasons to use this floor design is that it lowers the height of the shed so the shed floor is closer to the ground level making things easier to get in and out of the shed.

Concrete Slab: Pouring a concrete slab is the best way to build your shed floor if you plan on using the shed to store heavy items like motorcycles or ATV's. The cost of concrete is not much more than a framed floor but if you are not familiar with pouring concrete you may need to hire someone to pour the slab and this will increase the cost. Concrete slabs should have a thickened slab edge with 2 sticks of rebarn in them to hold up the weight of the shed walls. Check with your local building department to find out the recommended depth for shed edge footings.

Poured Piers: Concrete piers are made by using a round cardboard form and filling it up with concrete. Beams are set on top of the piers to hold the shed floor framing.

CMU Concrete Block Piers: These are similar to concrete piers but they are made from pre case concrete blocks stacked up. They hold beams that will in turn hold the shed floor framing.

Start Planning For Your Backyard Shed Today!

Planning is the most important step in building your backyard shed. A good set of plans and an accurate materials list will help you find the answers to the questions that need to be answered before and during construction. Some of these include:

- What style of shed should I build?

- How large of a shed can I build on my property? Check with your local building department and/or homeowners association to find out what the building restrictions are for your area.

- How large of a shed do I need? Only you can answer this one:)

- How large of a shed can I afford? Use the shed materials list to get an accurate cost of materials.

- Where do I want the shed on my property? Building codes will tell you how close the shed can be to your house and property lines. You may want the shed placed

- Will I have help to build the shed or will I build it myself?

ShedPlansBuild.com is here to help you build your backyard shed! With so many economy shed plans to choose from we are sure to have the design that you need to build your backyard storage shed. View the shed plans at the top of the page or view other plans on our site to find your perfect shed plans and start building today.